What's the difference between MDF and particle board?

When selecting furniture and designs for your home's interior, there is a wide range of materials available in the market. While solid wood has been a key material used in home décor, it can often come with a hefty price tag. To address cost concerns, furniture manufacturers have been exploring alternative materials that offer affordability without compromising quality. Two popular choices in the realm of home interior materials are Medium-Density Fiberboard (MDF) and particleboard.

MDF and particle board are both composite materials composed of various elements. In this blog, we will delve into the details of MDF and particleboard, highlighting the distinctions between the two.

Note: Please keep in mind that MDF and particleboard may not necessarily be cheaper alternatives to solid wood in all cases, as pricing can vary based on factors such as design, finish, and other considerations.

Application of industrial board

MDF Vs Particle-board: What is the Difference?

|

|

MDF |

Particle-board |

|

Look |

MDF features a smooth finish due to its consistent wood grain size.

|

Particleboard does not have a smooth surface, as it is composed of wood shavings and chips. |

|

Density |

MDF has a higher density level compared to particleboard.

|

Particleboard has a lower density level than MDF. |

|

Strength |

MDF is generally stronger than particleboard.

|

Particleboard is not as strong as MDF. |

|

Durability |

MDF is known for its durability.

|

Particleboard is relatively less durable. |

|

Weight |

MDF is heavier than particleboard.

|

Particleboard is lightweight. |

|

Moisture |

MDF exhibits better resistance to water.

|

Particleboard has lower resistance to water. |

|

Lifespan |

MDF can remain in good condition for up to 10 years.

|

Particleboard can last for up to 25 years. |

|

Price |

MDF is generally costlier than particleboard.

|

Particleboard is generally cheaper than MDF. |

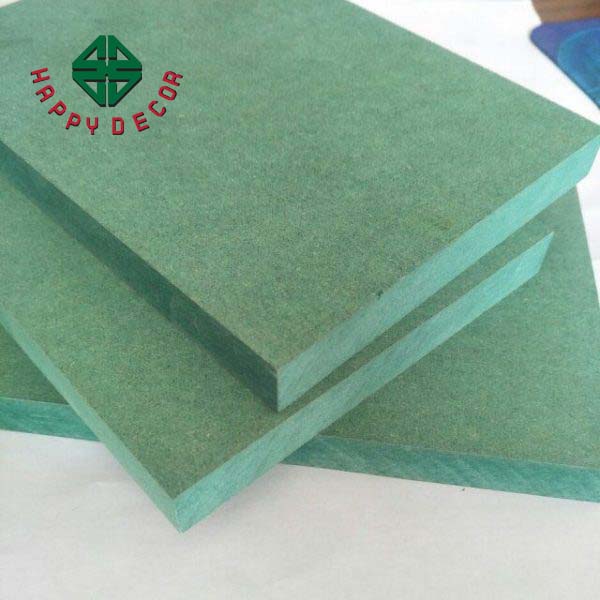

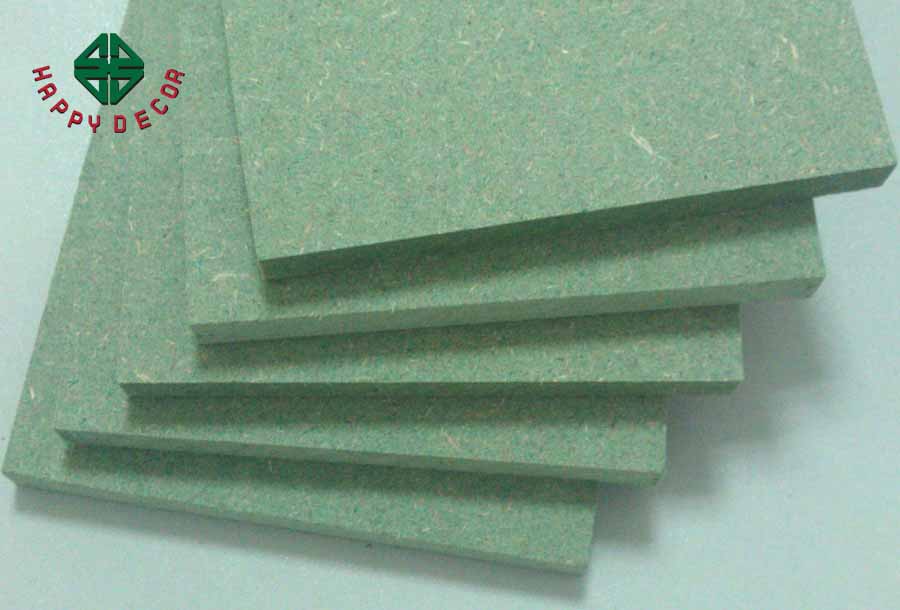

What is MDF?

MDF

See More: What is Moisture-Resistant LMR Board (Low Moisture Resistance)? Advantages and applications

MDF, short for medium-density fiberboard, is an engineered wood product made from wood fibers. These fibers are bonded together with glue and then subjected to high temperature and pressure to form a solid board. MDF is widely used in home décor due to its affordability. Its smooth finish provides a seamless surface for painting and creating intricate designs. With its strength and density, MDF is an excellent choice for various home interior applications.

Advantages of MDF:

MDF

- Affordability: MDF is a cost-effective option, making it accessible to a wide range of people seeking budget-friendly home décor materials.

- Eco-friendly: MDF is manufactured using a recycling process, making it an environmentally friendly choice.

- Smooth surface: MDF has a smooth and uniform surface, providing a sleek and polished look to furniture and interior designs.

- Paintability: MDF is highly receptive to paint, allowing for easy customization and the ability to achieve desired colors and finishes.

- Realistic finish: MDF can be laminated or veneered to mimic the appearance of natural wood grains, giving it a more realistic and sophisticated finish.

- Solid and dense: MDF is a solid and dense material, providing durability and stability to furniture and other applications.

- Easy to work with: MDF is relatively easier to drill, cut, and shape without the risk of damaging the material, offering flexibility in design and installation.

Disadvantages of MDF:

MDF

- Lack of strength: MDF is not as strong as natural wood, and under excessive stress, it can be prone to splitting or cracking.

- Water absorption: MDF has higher water absorption properties compared to wood, making it susceptible to swelling and potential damage when exposed to moisture.

- VOC emissions: MDF contains urea-formaldehyde, which releases volatile organic compounds (VOCs). Prolonged exposure to these VOCs can be harmful to the eyes and lungs.

- Dust production: During the manufacturing process of MDF, a significant amount of dust is generated, which can pose health risks if inhaled.

It's important to consider these factors when using MDF and take appropriate precautions to mitigate any potential drawbacks associated with its use.

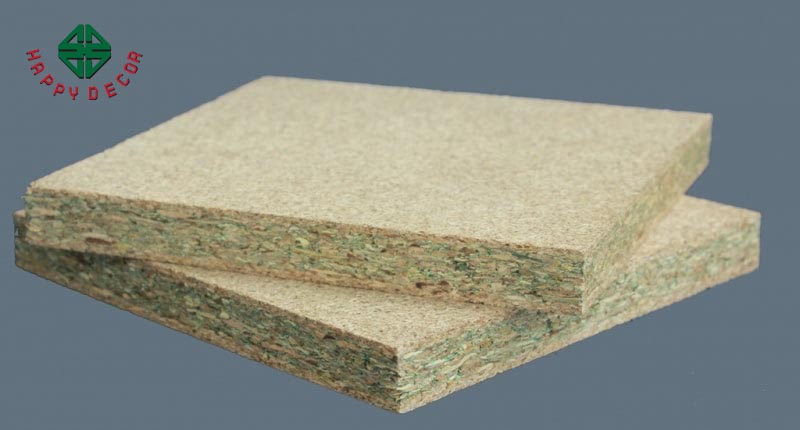

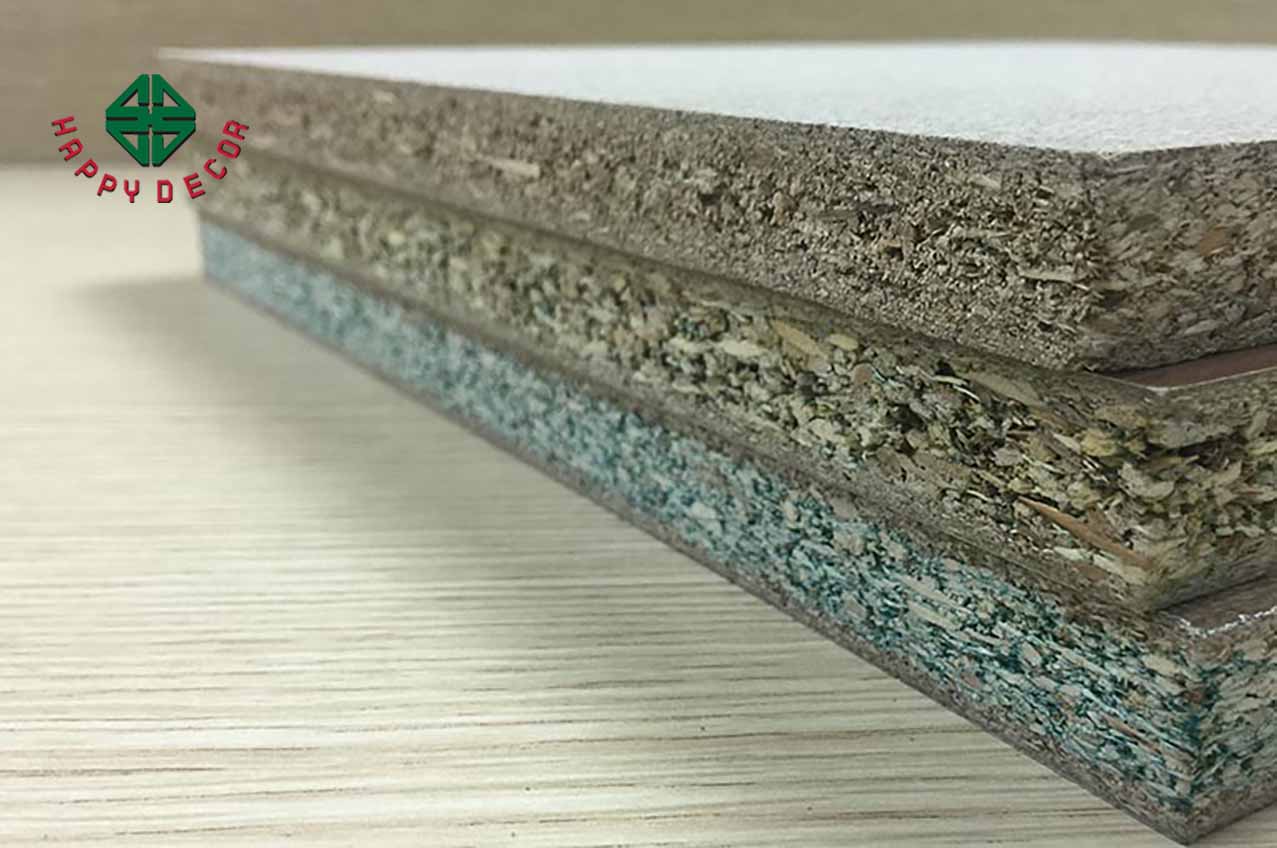

What is a Particle board?

Particle board

Particleboard, also known as chipboard, is a cost-effective product made from waste wood materials. It is created by combining resin and sawdust, which are then subjected to heat and pressure to form a solid board. Particleboard is commonly used in the production of affordable furniture and serves as an underlying layer for countertops. While it can be drilled into, caution must be exercised as particleboard is prone to tear-out.

To enhance its appearance, particleboard is often finished with a laminate or veneer. However, shaping or molding particleboard can be challenging as it has a tendency to break or chip.

Advantages of Particleboard:

Particle board

- Cost-effective: Particleboard is an affordable option compared to materials such as MDF, solid wood, and plywood.

- Lightweight: Particleboard is lightweight, making it easy to handle, carry, and transport.

- Nail and screw holding: Particleboard has better nail and screw holding capabilities compared to MDF.

- Easy maintenance: Particleboard is easy to clean and maintain.

- Versatility: Particleboard can be easily drilled, cut, milled, painted, glued, and modified to suit various design and construction needs.

- Eco-friendly: Particleboard is made from recycled waste wood products like sawdust, wood chips, and shavings, making it an environmentally friendly choice.

- Consistency: Particleboard lacks natural defects often found in solid wood, providing a uniform and consistent material for construction and manufacturing purposes.

- Soundproof properties: Particleboard exhibits soundproofing characteristics, making it suitable for applications such as auditoriums, speakers, and theatres.

- Compatible with veneer and laminate: The smooth and flat surface of particleboard allows for easy adhesion of veneer and laminate materials. Thin sheets of veneer or laminate can be easily glued onto the surface, enhancing its aesthetic appeal.

Disadvantages of Particleboard:

Particle board

- Lack of strength: Particle board is not as strong as other materials like plywood and MDF, making it more susceptible to damage if not handled with care.

- Low durability: Particle board has lower durability compared to other home interior materials, resulting in a shorter lifespan.

- Moisture sensitivity: Particleboard has low resistance to moisture and humidity, which can cause it to expand or deform when exposed to moisture.

- Potential health hazards: Some types of particleboard are manufactured using resins that may contain harmful chemicals, posing potential health risks.

These are important considerations when using particleboard in home décor projects. It's crucial to select high-quality materials that offer better durability and to ensure proper measures are taken to protect against moisture damage. If you're interested in home interior designs utilizing MDF and particleboard materials, HomeLane can provide you with a wide range of customizable solutions to meet your specific needs.

main.comment_read_more