What is Moisture-Resistant LMR Board (Low Moisture Resistance)? Advantages and applications

Moisture-Resistant LMR Board(Low Moisture Resistance) plays a crucial role in the realm of interior design and furniture manufacturing. Its significance lies in its ability to withstand the challenging weather conditions and high humidity levels often experienced in regions like Vietnam. Unlike natural wood, LMR Board does not succumb to warping, swelling, cracking, or termite damage, making it highly durable and long-lasting.

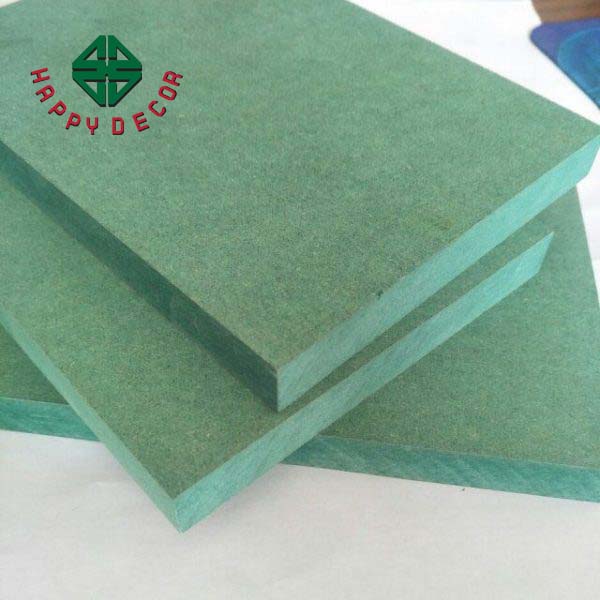

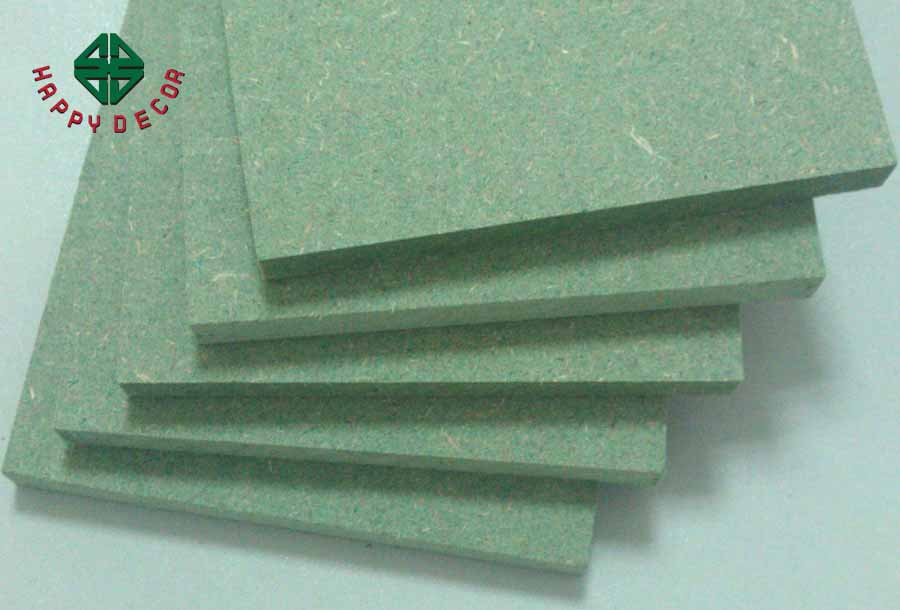

Moisture-Resistant LMR Board (Low Moisture Resistance)

Contect>>>Tại đây

Currently, there are many types of LMR Boards (Low Moisture Resistance) available on the market, originating from various domestic factories as well as imports from China, Malaysia, Indonesia, Thailand, and more. Alongside this, there are different qualities of LMR Boards, and not every furniture manufacturer can distinguish between them. To address this, Happyco would like to introduce the following information to our valued customers, so they can understand and identify the "standard" LMR Boards that best serve their production needs.

One type is the Moisture-Resistant LMR Board, which comes in various levels of moisture resistance. However, customers may not be fully aware of this issue when making the best choice for their interior spaces. Currently, the best moisture-resistant LMR Board is the V313, although it is often mistakenly associated with other moisture-resistant variants. As a pioneering supplier of this type of board in Vietnam, Happyco aims to provide the most suitable product for domestic users and guarantees the quality of this product line.

What is Moisture-Resistant LMR Board (Low Moisture Resistance)?

Moisture-Resistant LMR Board, also known as Low Moisture Resistance Board, is a medium-density fiberboard (MDF) with low moisture resistance properties. It is engineered to be resistant to warping, cracking, and termite infestation, unlike natural wood. The smooth and flat surface of LMR Board makes it easy to process and manufacture, and it is cost-effective. It offers a wide range of surface finishes, including veneer, acrylic, melamine, and laminate, making it suitable for various interior styles, from modern to classical, from luxurious to refined.

Applications

Moisture-Resistant LMR Board is commonly used in the production of furniture such as tables, chairs, kitchen cabinets, filing cabinets, office desks, conference tables, bookshelves, decorative shelves, beds, wardrobes, wooden doors, as well as for creating partitions in karaoke rooms, speaker enclosures, soundproofing materials, and advertising displays.

Advantages of Moisture-Resistant LMR Board

LMR Board, which stands for Low Moisture Resistance Board, is a medium-density fiberboard that has low moisture resistance properties. Unlike natural wood, LMR Board is not prone to warping, cracking, or termite infestation. It has a smooth and flat surface that is easy to process and manufacture. LMR Board is cost-effective and offers a diverse range of surface finishes, including veneer, acrylic, melamine, and laminate, making it suitable for various interior styles, from modern to classical, from luxurious to refined.

Adaptability to Weather Conditions

Vietnam's climate can be harsh for many interior materials, especially in the northern regions where there are significant variations in humidity and temperature. LMR Board has undergone rigorous testing cycles, lasting 21-28 days, including 3 days of water immersion at 20 degrees Celsius, 1 day of freezing at -12 to -15 degrees Celsius, and 3 days of heating at 70 degrees Celsius. This ensures that LMR Board can adapt to any environment and climate conditions, particularly in the cold and dry winter and the damp spring of northern Vietnam.

Different Levels of Moisture Resistance

There are different types of moisture-resistant LMR Boards available, each with varying levels of moisture resistance. However, customers may not be fully aware of this aspect when making the best choice for their interior spaces. Currently, the best moisture-resistant LMR Board is still being equated with other moisture-resistant variants. As a pioneering supplier of this type of board in the Vietnamese market, Happyco aims to provide the most suitable products for domestic users and ensures the quality of this product line.

Moisture-Resistant LMR Board (Low Moisture Resistance)

Contect>>>Tại đây

LMR Board with moisture resistance performs better than HMR Board

Currently, HMR Board is highly regarded for its moisture resistance capabilities in the market. Even furniture manufacturers consider it the best option. However, in reality, moisture-resistant boards are segmented from low to high, including LMR (Low Moisture Resistance), MMR (Medium Moisture Resistance), HMR (High Moisture Resistance), and V313 boards. LMR Board contains 21-24% moisture-resistant components in the adhesive, while HMR Board contains 12-15%. LMR Board has a light yellow color with a smooth and uniform surface. MDF is preferred by manufacturers because it is easily customizable for production processes and has a lower cost for finished products, making it popular among customers. Another notable detail is the surface variety of the board. MDF coated with melamine alone offers up to 250 different color codes. Currently, there are premium color codes available in the market. Some medium-level color codes include Picomat, Dongwha, and TaLaB, which offer a wide range of natural wood grain colors as well as modern and sophisticated colors not found in natural wood. Additionally, there are MDF boards with veneer, adhesive paper, paint, laminate, and acrylic coatings.

Suitable for Diverse Usage Needs

Interior furniture items such as cabinets, shelves, and racks are prone to wobbling, breaking, or distorting when subjected to heavy loads due to the storage of numerous items. In addition to meeting the requirements for dimensional stability, LMR Moisture-Resistant Board also exhibits superior characteristics in terms of internal bonding strength, tensile strength, and resilience. Hence, it is a perfect choice for furniture pieces that endure significant weight.

Currently, the market offers the following products: MDF Board, which is a medium-density fiberboard; LMR Board, a high-density fiberboard; and LDR Board, a low-density fiberboard. From an external appearance perspective, it is challenging for customers to differentiate between them as they share a similar light yellow color. However, the quality of these boards varies significantly. Many vendors sell LDF panels but misadvise customers by suggesting LMR, which has tarnished the reputation of genuine LMR boards and led to price erosion in the competitive market. This has caused difficulties for legitimate LMR sellers.

Furthermore, moisture-resistant LMR Board has various applications in interior design. It is used in the production of furniture such as tables, chairs, kitchen cabinets, office desks, conference tables, bookshelves, decorative shelves, beds, wardrobes, wooden doors, karaoke room partitions, speakers, soundproofing materials, and advertising displays. LMR Board does not warp, crack, or attract pests like natural wood. It offers a smooth, flat surface that is easy to process and manufacture. With its affordable cost and diverse range of surface finishes, including veneer, acrylic, melamine, and laminate, it is suitable for various interior styles, from modern to classical, from luxurious to refined.

main.comment_read_more