Types Of Plywood Commonly Used In Furniture

There is no industry that has as abundant and diverse raw materials as the furniture industry, especially when it comes to wood furniture. With the advancements in science and technology, new materials have been introduced to supplement and gradually replace traditional natural wood. Plywood is a prime example of such a material. So, what are the outstanding advantages of plywood, and what are the limitations that need to be addressed? How is it applied in interior design?

What is plywood?

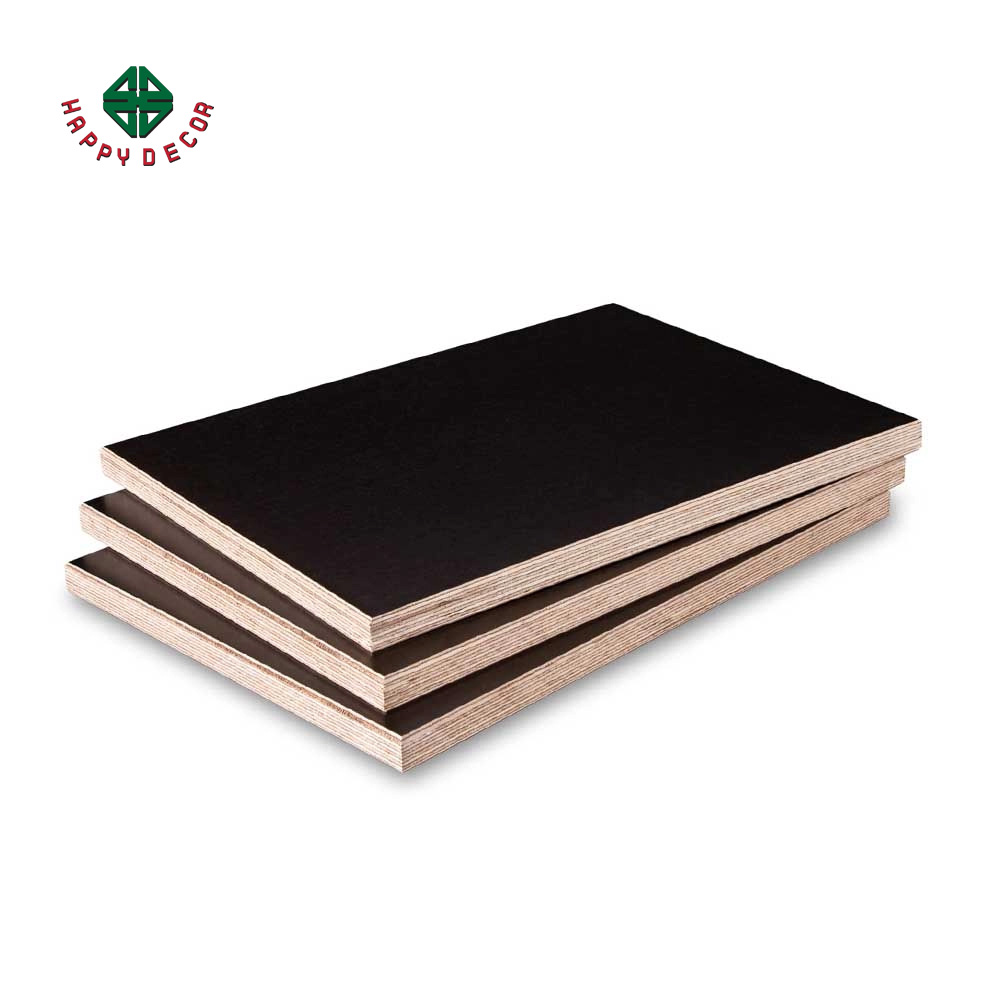

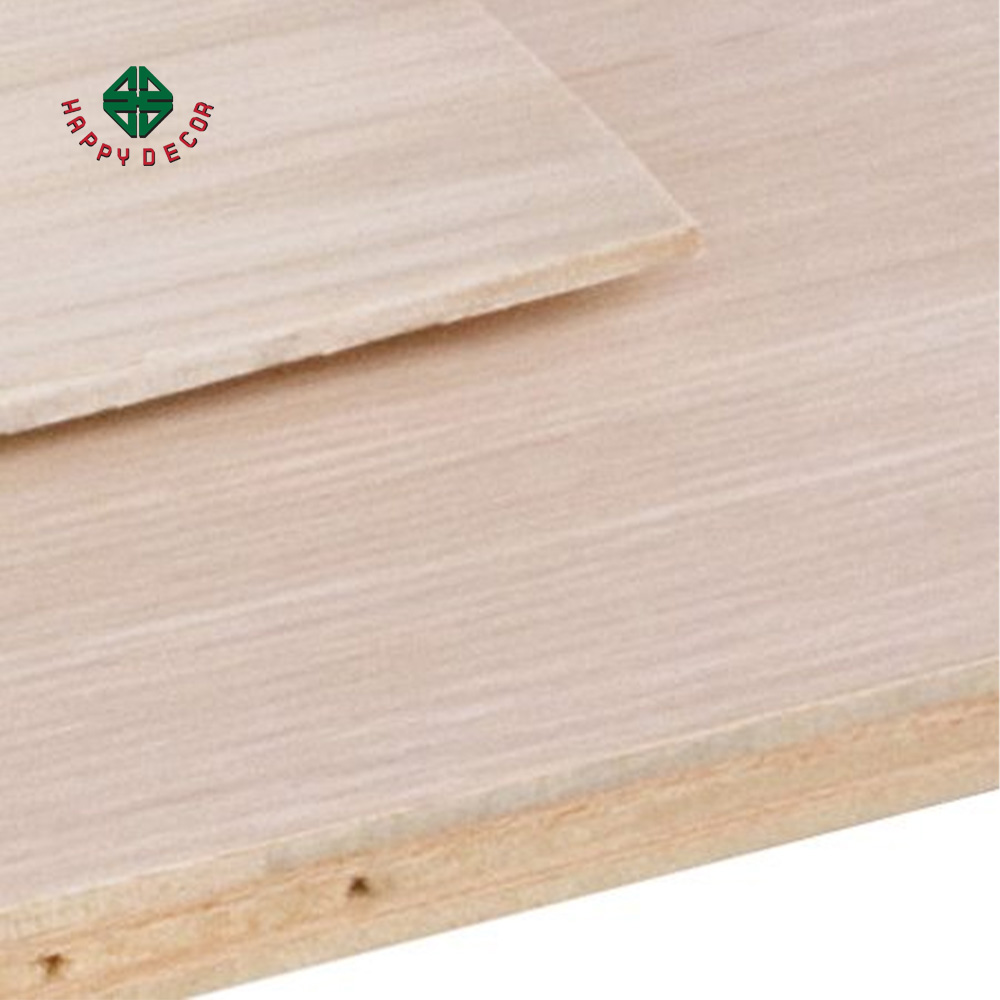

Plywood

Contact >>>Here

Plywood, also known as engineered wood, is a type of material produced by bonding together thin layers of wood veneers. These adjacent layers have beautiful wood grains, with alternating grain directions at a 90-degree angle. The alternating pattern of these wood fibers is called cross-graining and it offers several important benefits. It reduces the tendency of wood to split when nails are driven near the edges. Additionally, it minimizes warping and shrinking, providing stability to plywood sheets.

1. History of plywood formation

Plywood, often referred to as engineered wood, is an innovative product in the field of wood technology that originated in the 1980s in New York, USA. By the early 1990s, we witnessed the establishment of plywood production plants by state-owned companies in Vietnam. Plywood is understood as a type of wood panel created by stacking multiple veneer sheets of the same size on top of each other. The stacking process is continuously carried out, aligning the wood grains of each layer.

2. Structural features of plywood plywood

Plywood

Contact >>>Here

A typical plywood sheet consists of a higher-grade outer layer compared to the thinner inner veneer layers. The main function of the core layers is to increase separation between the outer layers where the highest bending stresses occur. This enhances the bending resistance of the plywood sheet as a whole. Consequently, thicker sheets can span larger distances under the same load. When bent, the highest stresses occur in the outermost layers, with one layer experiencing tension and the other experiencing compression. The bending stresses decrease from the maximum at the face layers to nearly zero at the center layer. Conversely, shear stresses are higher at the center of the sheet and in the outermost fibers. In Europe, basic plywood can be categorized into three main types: birch plywood (approximate density of 680 kg/m3), mixed plywood (approximate density of 620 kg/m3), and softwood plywood (density ranging from 460 to 520 kg/m3).

Types of plywood boards today

Depending on the chemical technology used, plywood nowadays employs two main types of adhesives: phenol-formaldehyde and formaldehyde-based adhesives. Among them, phenol-based adhesives are known for their water resistance, making them more widely used in interior decoration. These types of plywood are often marketed as water-resistant plywood or moisture-resistant plywood. As for the wood species used in plywood construction, some common ones include:

1. Poplar Plywood:

Poplar Plywood

Contact >>>Here

Poplar plywood, meeting the CARB 2 standards of the United States, has the following specifications:

- Standard Size: 1220mm x 2440mm (4'x8')

- Face Veneer: Imported A/A, A/B peeled poplar

- Core Layers: Engineered wood (veneer, poplar, rubber, etc.)

- Adhesive: MR-Ure Formaldehyde, E0 standard

- Thickness: 3mm, 5mm, 7mm, 9mm, 12mm, 15mm, 18mm, 25mm

- Tolerance: ± 3%

- Moisture and water-resistant product

- Resistant to boiling water and termite damage due to preservation.

2. Walnut Plywood:

Walnut Plywood

Contact >>>Here

Walnut plywood, meeting the CARB 2 standards of the United States, has the following specifications:

- Standard Size: 1220mm x 2440mm (4'x8')

- Face Veneer: Imported A/A, A/B peeled walnut

- Core Layers: Engineered wood (veneer, poplar, rubber, etc.)

- Adhesive: MR-Ure Formaldehyde, E0 standard

- Thickness: 3mm, 5mm, 7mm, 9mm, 12mm, 15mm, 18mm, 25mm

- Tolerance: ± 3%

- Moisture and water-resistant product

- Resistant to boiling water and termite damage due to preservation.

3. White Oak Plywood:

White Oak Plywood

Contact >>>Here

White oak plywood, meeting the CARB 2 standards of the United States, has the following specifications:

- Standard Size: 1220mm x 2440mm (4'x8')

- Face Veneer: Imported A/A, A/B peeled white oak

- Core Layers: Engineered wood (veneer, poplar, rubber, etc.)

- Adhesive: MR-Ure Formaldehyde, E0 standard

- Thickness: 3mm, 5mm, 7mm, 9mm, 12mm, 15mm, 18mm, 25mm

- Tolerance: ± 3%

- Moisture and water-resistant product

- Resistant to boiling water and termite damage due to preservation.

4. Ash Plywood:

Ash Plywood

Contact >>>Here

Ash plywood, meeting the CARB 2 standards of the United States, has the following specifications:

- Standard Size: 1220mm x 2440mm (4'x8')

- Face Veneer: Imported A/A, A/B peeled ash

- Core Layers: Engineered wood (veneer, poplar, rubber, etc.)

- Adhesive: MR-Ure Formaldehyde, E0 standard

- Thickness: 3mm, 5mm, 7mm, 9mm, 12mm, 15mm, 18mm, 25mm

- Tolerance: ± 3%

- Moisture and water-resistant product

- Resistant to boiling water and termite damage due to preservation.

5. Other Plywood Varieties:

Apart from the commonly used wood core species, plywood surfaces can also be coated with Pine, Okume, Engineered, Brich, or Sapele veneers. However, the types mentioned above are the most popular and widely used in the interior decoration industry and cater to the preferences of Vietnamese consumers.

We hope this information about plywood varieties will be helpful in your work. If you have a need for furniture made from plywood, please call 0932 12 15 19 for consultation. As an interior design and construction company with our own carpentry workshop, we offer direct production at very competitive prices.

main.comment_read_more