What is film faced plywood?

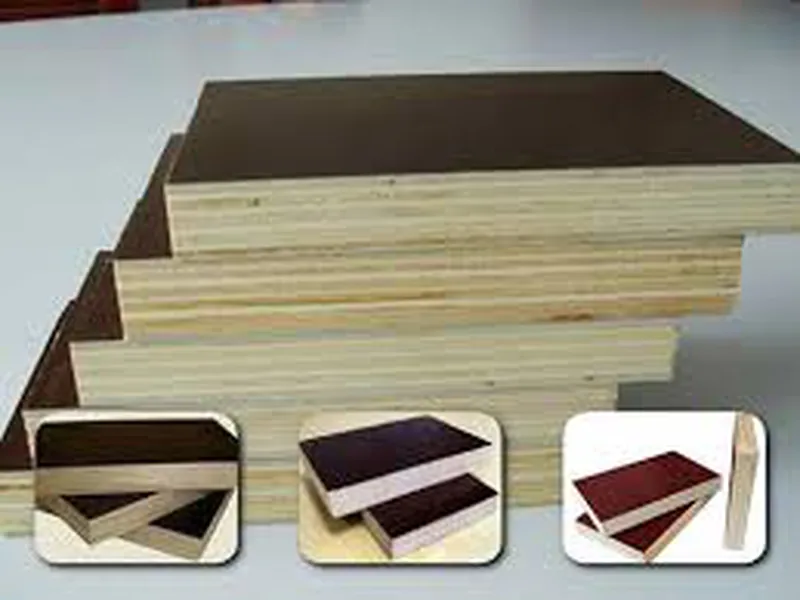

Film faced plywood

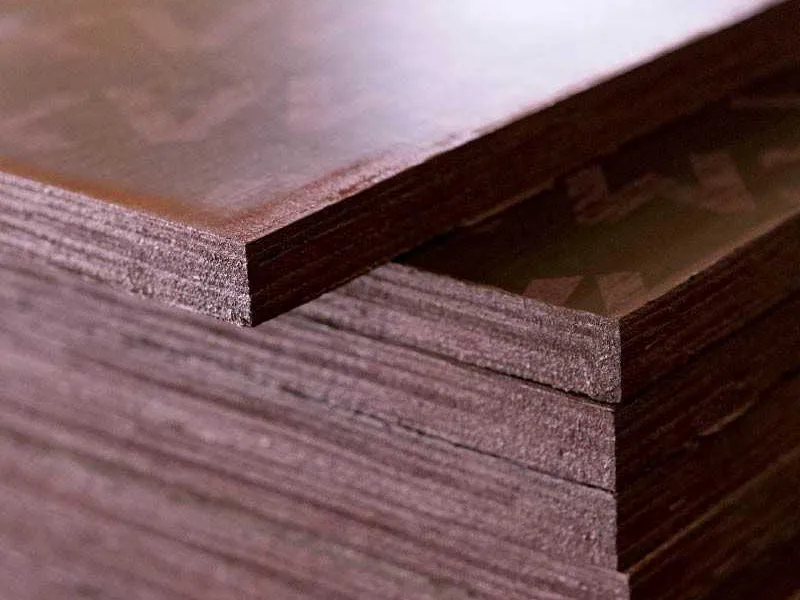

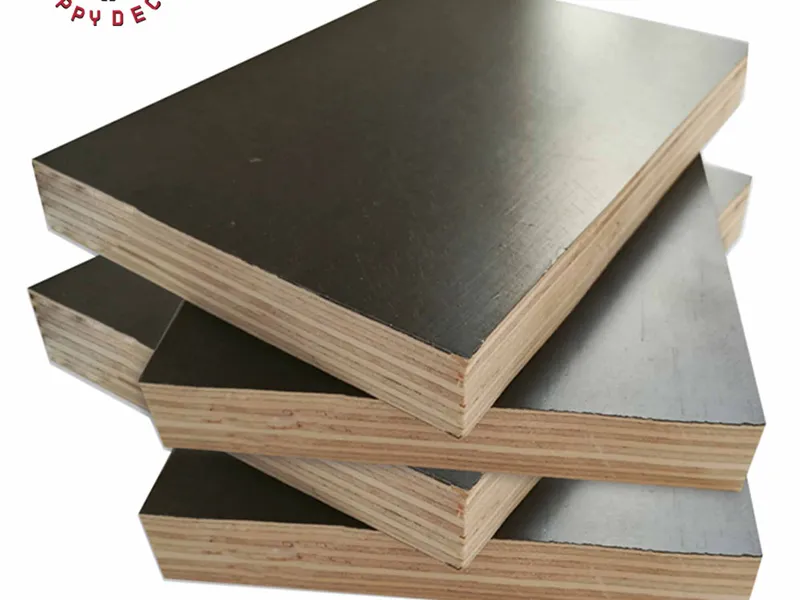

Film faced plywood is an industrial plywood made by hot pressing wood layers together with a high quality water and moisture resistant glue (usually WBP or MR glue). Film-coated plywood is also covered with a film layer that is waterproof, and creates a smooth, glossy finish, capable of reducing scratches and protecting the board during installation and construction.

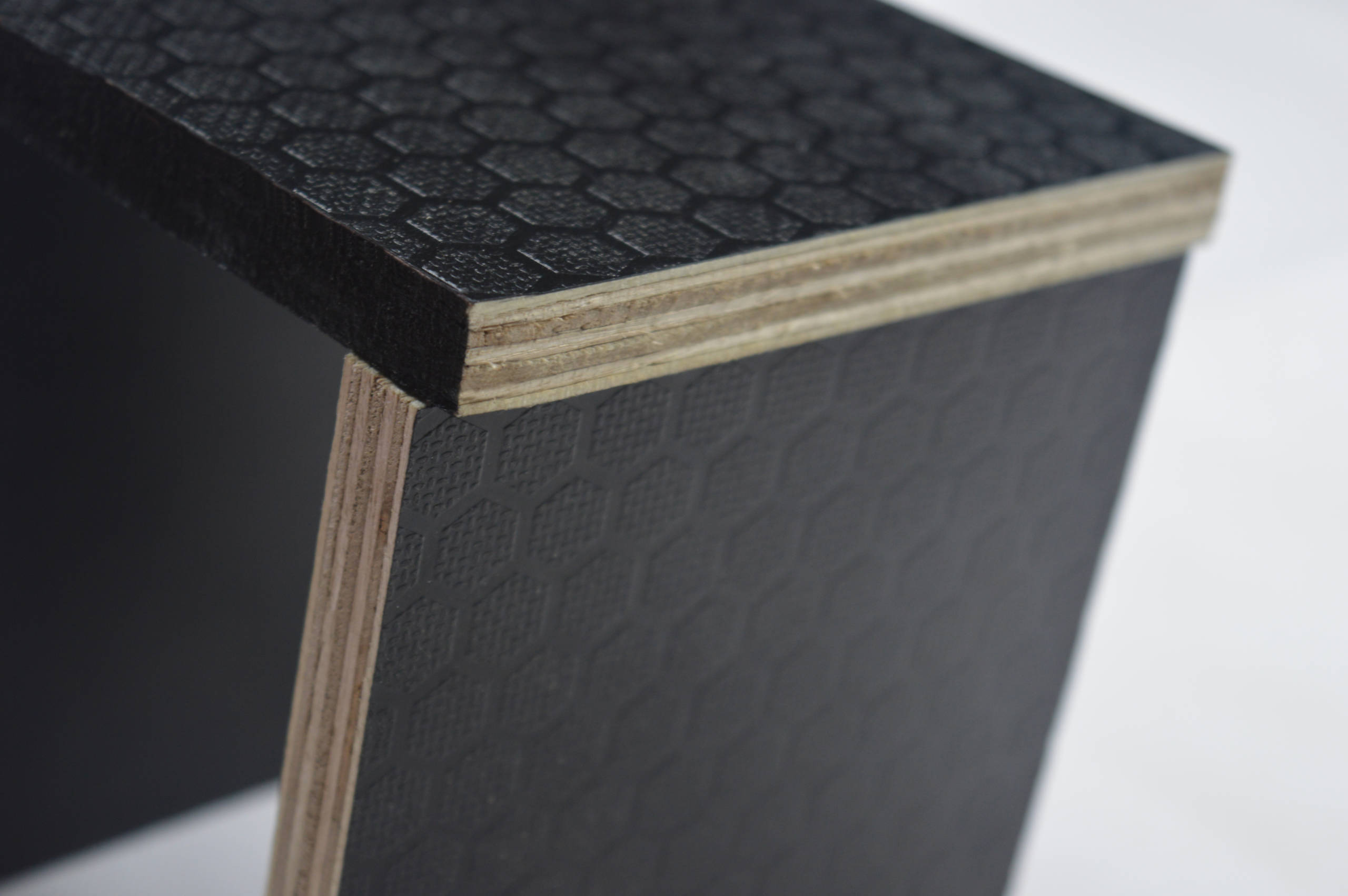

Composition of film faced plywood

Film faced plywood

Film faced plywood glue

Formwork glue is a very important component, it is the main factor determining whether the formwork can withstand water in the process of making formwork in construction or not. Usually we have 2 main types of plywood glue:

WBP (Water Boiled Proof) is an English name that means water-resistant glue, not a separate name for the glue. Glues with water-resistant properties can all be referred to as WBP glues.

Film coppha

Film faced plywood

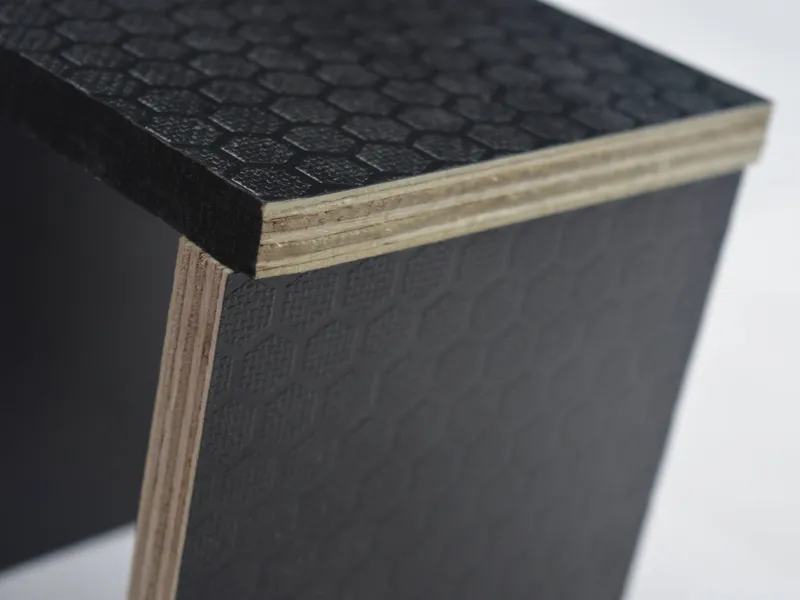

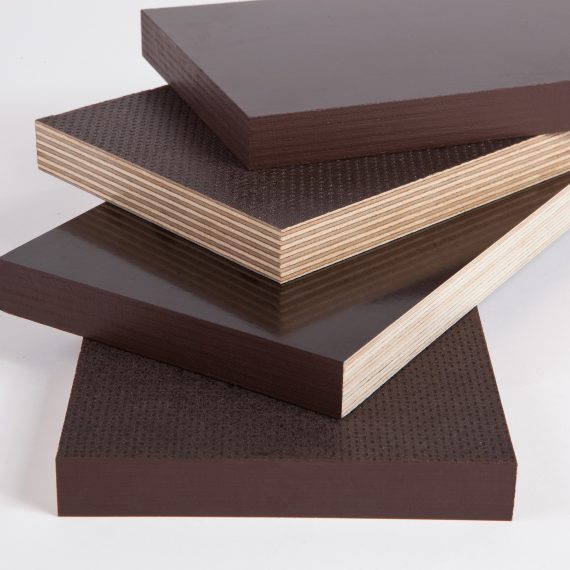

The main film is a waterproof Phenolic glue film, it helps to create a smooth-glossy finish, limit scratches as well as protect the board during construction and use.

Film faced plywood core

Wood type: the types of wood used to make film faced plywood are: Eucalyptus, Pine, Hardwood, Polar, Birch and Combi...

Classification of boards by quality: there are 7 types in descending order of quality AA, A+, A, B+, B, C+ and C

Advantages of using film faced plywood

Film faced plywood

– The film faced plywood surface is absolutely flat, making the concrete floor surface completely flat after construction and no need to add mortar.

– Light weight, easy and convenient to move, easy to install and construct.

- Easy to cut into many sheets to use.

– The board is not waterproof, can be reused many times (6-10 times) to save costs.

main.comment_read_more