Benefits of plywood with a film coating for formwork

Advantages of Film-Coated Plywood for Interior Applications

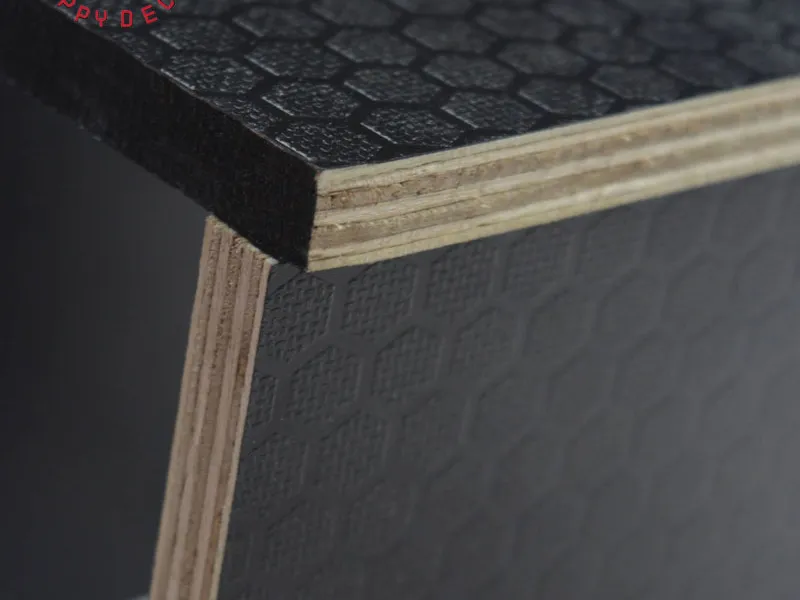

Film Faced Plywood

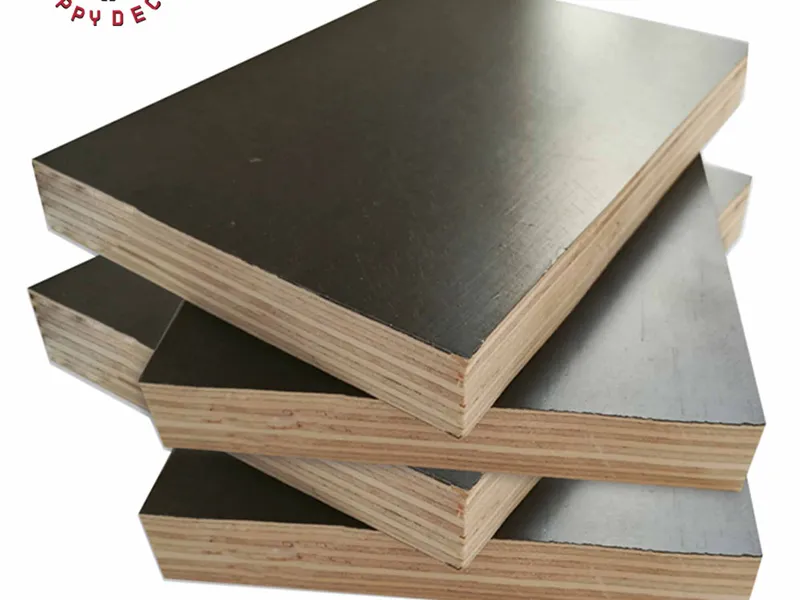

a. Durability:

Film-coated formwork plywood is highly durable due to its specific PET layer with anti-wear properties. It is resistant to fungal growth and can withstand varying weather conditions. The plywood is treated with top-quality wood treatment and modern technology, providing strong chemical resistance and a longer lifespan.

b. Excellent Moisture and Water Resistance:

Film-coated plywood is designed with an exterior film covering surface, making it highly resistant to moisture and water. This feature is particularly useful for outdoor applications where direct contact with water and aluminum needs to be minimized.

c. Easy to Clean:

The film coating on plywood creates a smooth and resistant surface, making it easy to clean. A simple wipe with a cloth is sufficient to maintain its cleanliness, saving time and effort.

d. Reusability:

Film-faced plywood is suitable for both indoor and outdoor use. It finds applications in construction as well as furniture making. It is commonly used for molding ceilings, walls, sewers, highways, house columns, and more. The plywood can be reused multiple times, typically having a life cycle of 5-8 uses, depending on the glue and wood type. This reusability factor helps reduce investment and labor costs for investors.

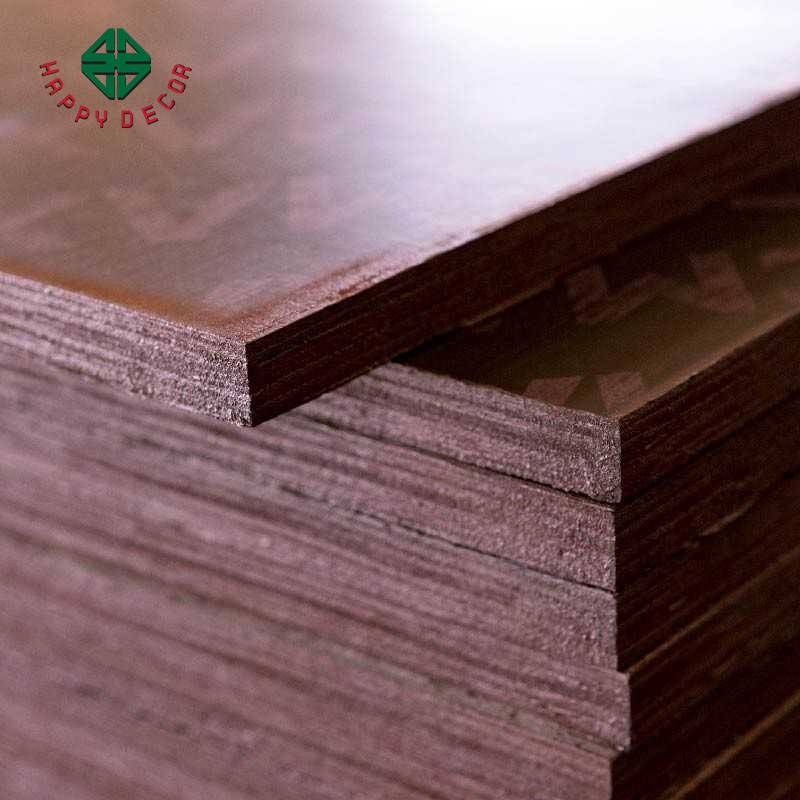

Film faced formwork plywood production process

Film Faced Plywood

The production process of film-coated formwork plywood follows similar steps to other types of plywood. It involves cutting wood, drying, hot and cold pressing to create a bond between wood layers. However, film-faced formwork plywood undergoes an additional step of film coating and edge painting to enhance aesthetics and functionality.

When choosing film-coated plywood, it is important to consider the type of glue used. Water-resistant glues, such as WBP (Water Boiled Proof), including phenolic, melamine, and MR (Moisture Resistant), are preferred. The core of the plywood is typically made from hardwood, eucalyptus, birch, oak, or mixed wood, and HappyCo classifies plywood based on the quality of the core wood.

Things to keep in mind when choosing film-coated plywood

Considerations when Choosing Film-Coated Plywood for Interior Design

Adhesive:

The adhesive used in film-coated plywood is a critical factor in determining its water resistance. There are two main types of adhesives: WBP (Water Boiled Proof), which includes phenolic, melamine, and MR (Moisture Resistant) adhesives known for their excellent moisture resistance properties.

Film Faced Plywood

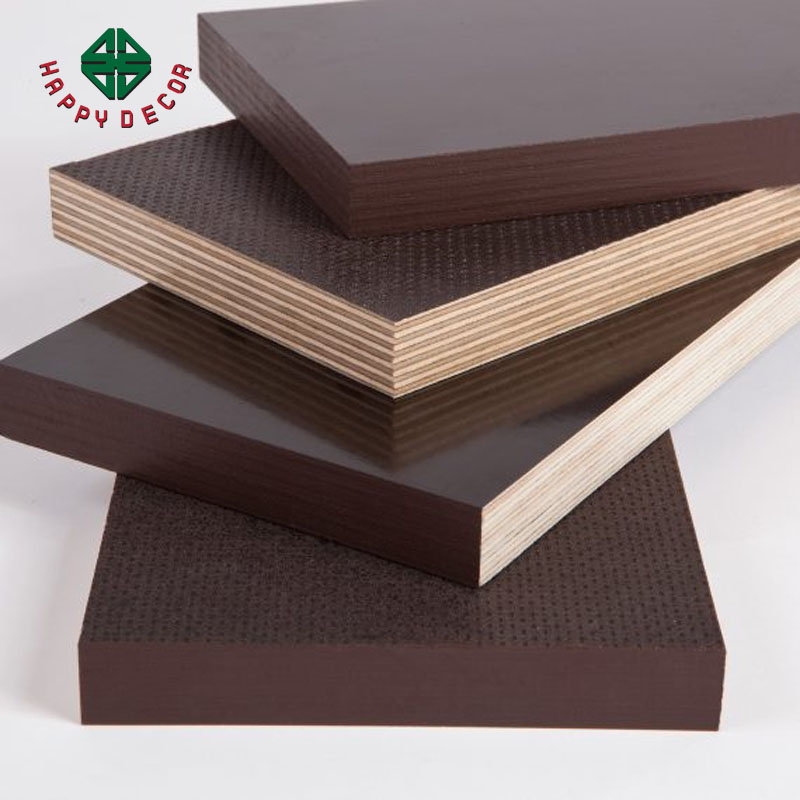

Core:

The core of film-coated plywood for interior design is typically made from hardwood, beech, birch, oak, or mixed wood. HappyCo categorizes plywood based on the quality of the core wood.

- Grade AA: High-quality full-face wood veneer, with at least three hot-pressed plywood cores, minimal thickness tolerance, suitable for export.

- Type AB: High-quality plain-face wood, with 2-3 hot-pressed plywood cores, a flat surface, and low thickness tolerance.

Film:

HappyCo utilizes premium film brands such as Dynea and Stora Enso, known for their durability, aesthetic appeal, and high-quality performance. These films are commonly used for producing high-quality film-coated plywood for interior design applications.

When selecting film-coated plywood for interior design purposes, it is important to consider the type of adhesive used, ensuring its water resistance. The choice of core wood should be based on its quality and suitability for the intended interior design project. HappyCo offers a range of plywood grades to meet different requirements. The films used are of high quality, providing durability, visual appeal, and reliability to the finished plywood products.

For detailed advice or inquiries regarding our high-quality film-coated plywood for interior design, please contact HappyCo.

main.comment_read_more